Road roller for tractor:

Road roller for tractor The primary rollers were steam-powered, later they were modified to Diesel engines. Modern rollers are urbane machines with Hydraulic drive, adjustable compaction, and scenic operator cabins. That replace to suit the way of travel. In several parts of the world, road rollers are still known conversationally as steam rollers, irrespective of their technique of force. This typically only puts on to the main examples (used for road-making).

Uses:

Preliminary compaction of the substrate is done using a pneumatic-tired roller, in its place of the solitary- or double-drum is replaced by two rows (front and back) of pneumatically filled tyres. The suppleness of the tyres, with a sure amount of vertical drive of the wheels, allows the roller to operate efficiently on rough ground. The finish is thru using metal-drum rollers to ensure a smooth, even outcome. Such compactors characteristically have sprags (‘sheep’s-foot’) wheels and do not try to attain a smooth surface.

Variations and features:

- On some apparatuses, the drums may be occupied with water on-site to attain the anticipated vehicle weight. When not filled, the lighter machine is calmer and inexpensive to transport between work sites.

- Extra compaction may be accomplished by pulsating the roller drums.

- Water lubrication may be provided to the drum exterior to avoid hot asphalt (for instance) sticking to the drum

- Hydraulic transmission permits better design flexibility (initial examples were direct mechanical drive) and decreases the number of moving parts visible to pollutants of building sites

- Human-propelled rollers may solitarily have a single roller drum

- Self-propelled rollers may have two drums, an equestrian one in front of the supplementary (format recognized as ‘duplex’), or three rolls, or just one. Moreover, With the back rollers substituted with treaded air-filled tyres for amplified traction

- Over the years many strange machines have been built for professional operations. Moreover, Including one machine with enormous twin drums for a dam-building contract to compressed the clay core.

About Our Vibratory Rollers:

Vibratory Road roller for tractor turns a sideslip steer into an influential compactor, superlative for asphalt patch, basis, trench, and flatwork compaction. Moreover, They’re very cost-effective since owning one removes the costs and preservation of a self-propelled roller.

About Our Roller Levels:

Designed for trifling preservation and all-out uptime, roller levels thrash clumps and clods for an evener finish in loose soil. Moreover, the Front roller position offers passable visibility and offers total control when contouring, grading, cutting and flattening flat or slanted land.

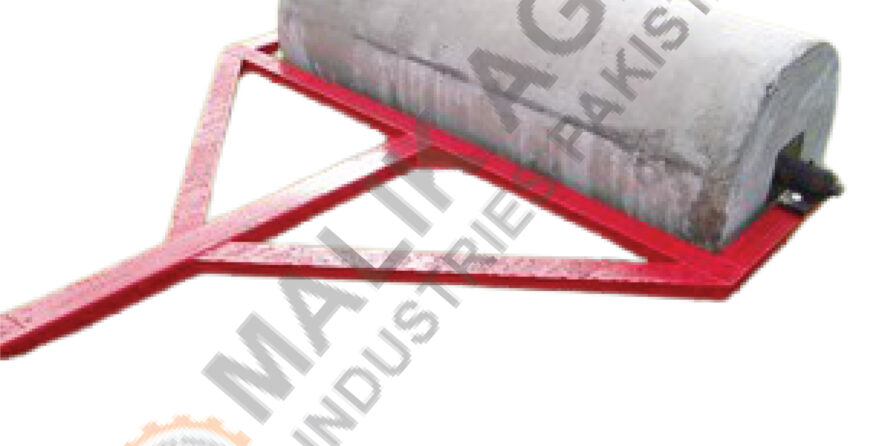

Grid rollers:

Grid rollers are a sort of roller that has a system of steel bars, which make a grid-like pattern on the steel drum. The grid may also be ballasted with concrete blocks or steel add-ons for more contact compression. While These types of rollers are usually pulled or hauled behind a tractor or additional heavy machine.

The grid design on the cylinder drum produces a high interaction compression with little reflexology action on compaction work. Because of this, they’re most appropriate on well-graded, rough soils, worn rocks, and subgrade and sub-base road constructions.